candy dispenser

stanford university, foundations of product realization, winter 2022

sketching, prototyping, mechanism design, cad (fusion 360), laser cutting + 3d printing

overview

goal: create a mechanical candy dispenser that meet the following requirements:

actuated by rotational motion

automatically reset after actuation

dispense only one candy per actuation

store at least 20 artificial candies

include a controlled, specific location for dispensed candy

include a spring subject to a preload, hard stops, and a purely linear load between endpoints

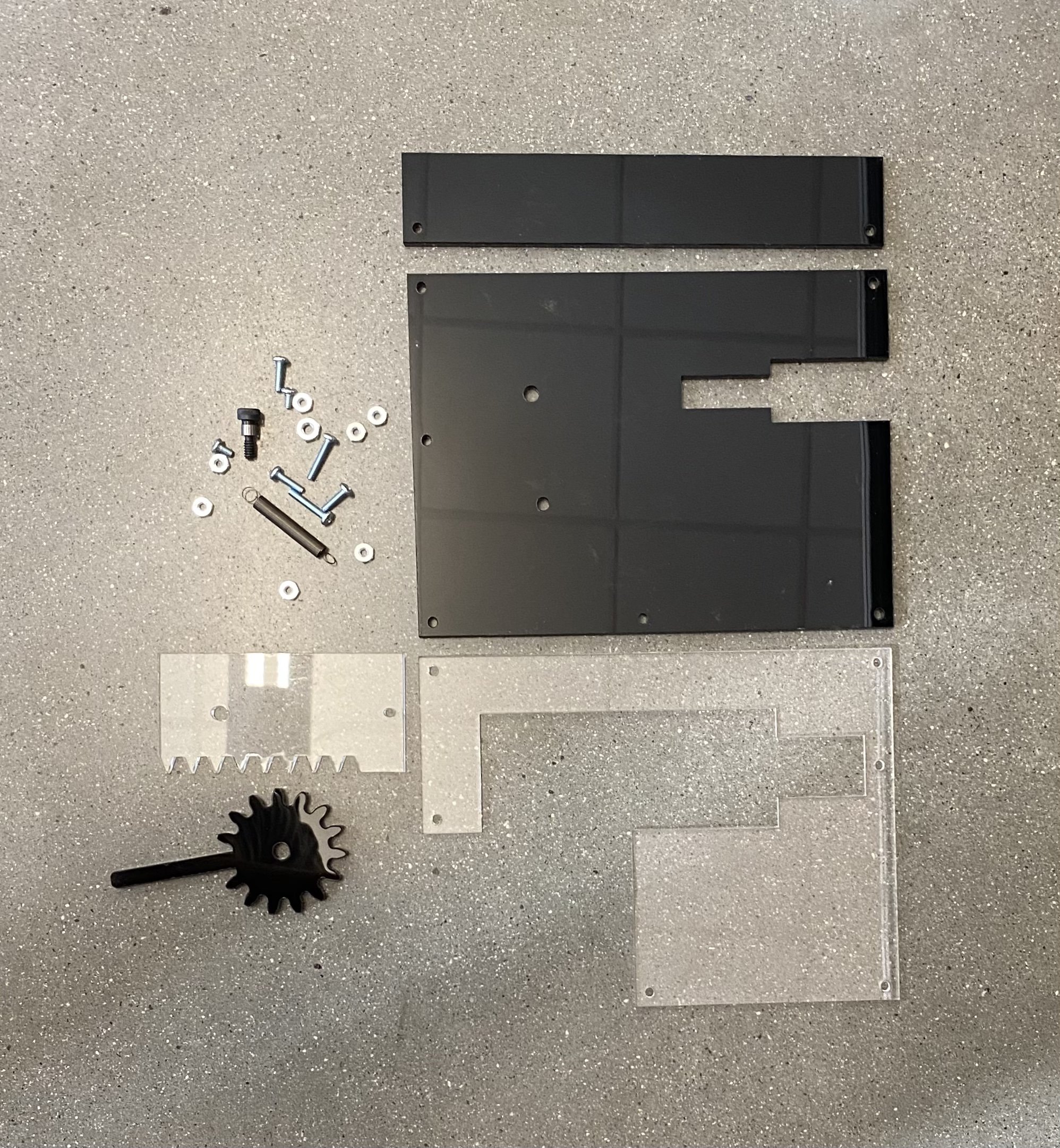

design components:

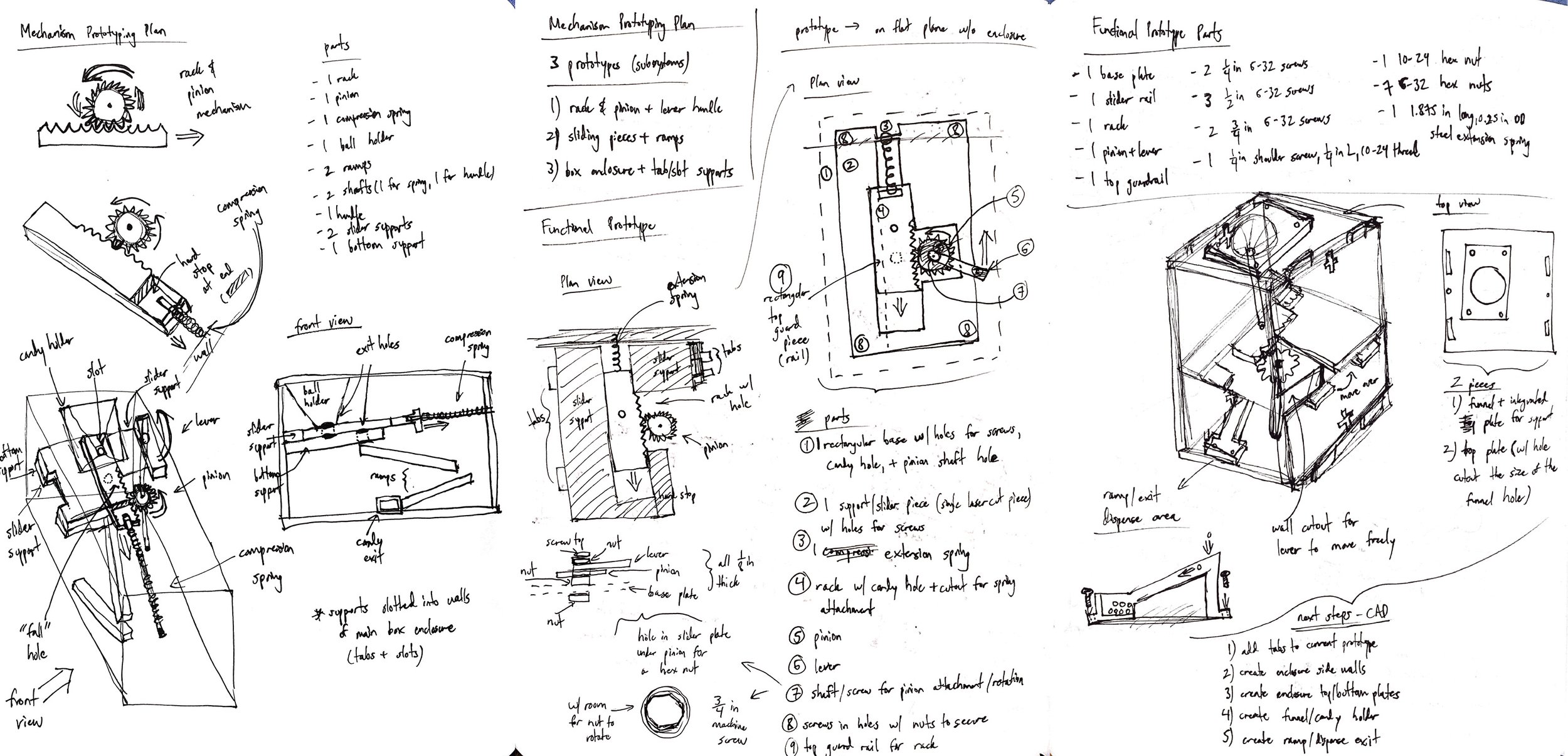

rack and pinion mechanism (rotation of spur gear linearly translates rack)

funnel candy holder + slide/dispensed candy holder

extension spring (2.125” preload length, 3.125” maximum extension length)

tabs and slots (for walls and floor plates) and t-slots (for screws and nuts) for simple, robust assembly

screws (6-32, 4-40, and shoulder screw) and hex nuts

unthreaded rubber bumpers (for stability on tabletop)

fabrication:

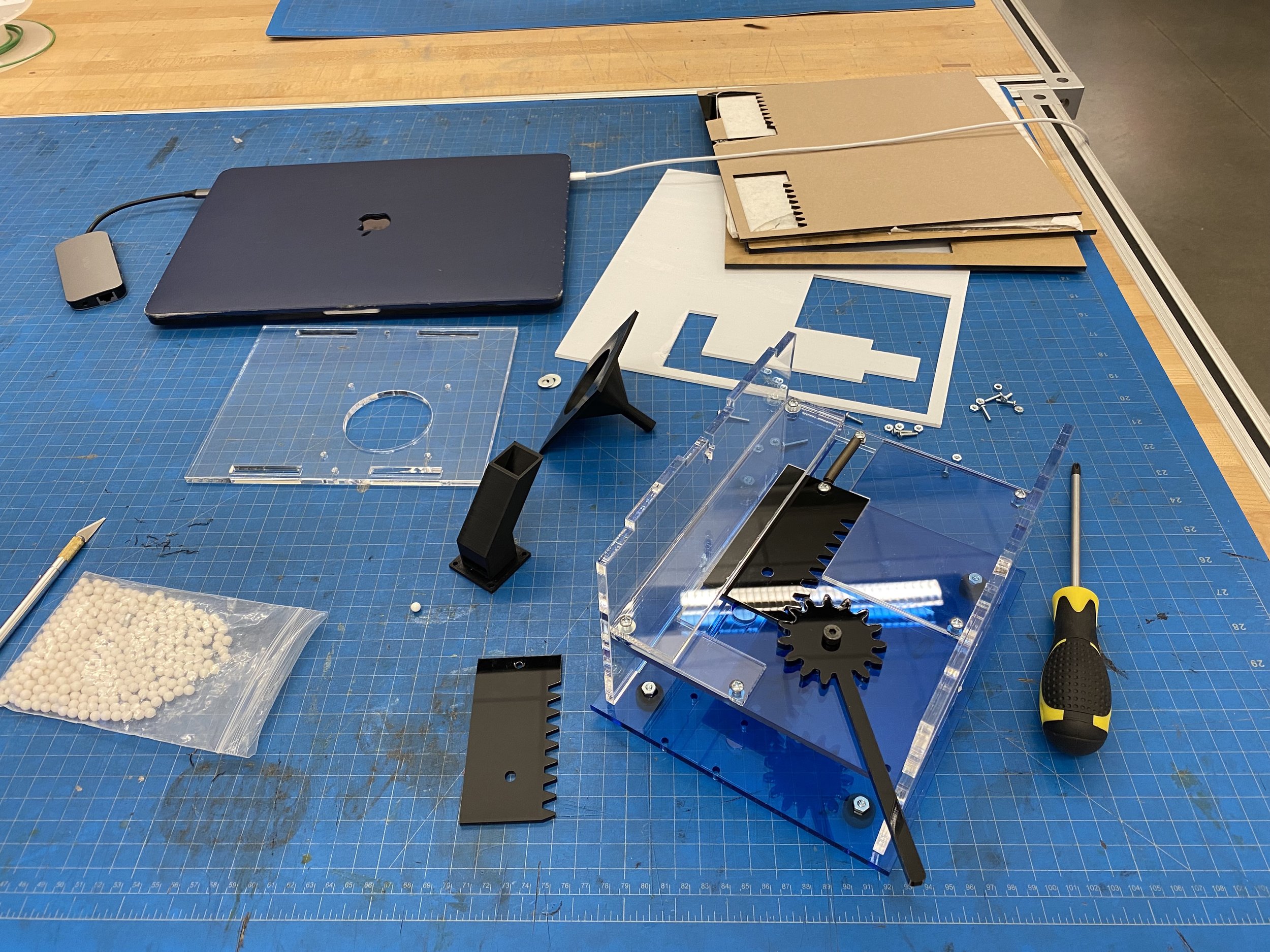

entire assembly laser cut, except for funnel + slide/dispensed candy holder (3d printed)

drawings

sketching

prototyping

story

A candy dispenser, using a simple rack and pinion mechanism and an extension spring. With smooth, precise movements and crisp sounds as the candies drop effortlessly into place, this machine is reliable, robust, and a joy to operate.